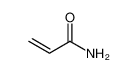

poly(acrylamide) macromolecule

CAS NO.: 9003-05-8

Purity :99%

| Compound | Polyaluminium Chloride | ||||

|---|---|---|---|---|---|

| CAS No. | 101707-17-9 | Catalog No. | 絮凝剂 | Brand | |

| Purity | 26% | Packing | 1ton | Grade | |

| Lead Time | 3Day (s) | Origin | Loading Port | ||

Polymeric aluminum chloride is a water purification material, inorganic polymer coagulant, also referred to as polyaluminum, abbreviated as PAC, due to the bridging of hydroxide ions and the polymerization of polyvalent anions, the molecular weight is relatively large. High charge inorganic polymer water treatment agent. In terms of morphology, it can be divided into solid and liquid. The solids are divided into Tan, beige, golden yellow, and white according to the color. The liquid can be colorless, transparent, yellowish, light yellow to yellow-brown. Polymerized aluminum chloride of different colors also has great differences in application and production techniques.

Main purpose

1. It is a flocculant, which is mainly used for the purification of drinking water and special water quality treatment for water supply, such as iron removal, fluorine removal, cadmium removal, radioactive pollution removal, oil slick removal, etc.. It is also used for industrial wastewater treatment, such as printing and dyeing wastewater. In addition, it is also used for precision casting, medicine, papermaking rubber, tanning, petroleum, chemicals, and dyes. 2. Polyaluminum chloride is used as a water treatment agent in surface treatment. 3. The main raw materials of perspiration cosmetics. 4. Some flocculants can be used in food additives.

Water purification principle

Compressed double layer[ 2]

The structure of the colloidal double layer determines that the concentration of antiions at the surface of the colloidal particle is the largest, and the higher the distance from the surface of the colloidal surface, the lower the antiion concentration, and eventually the ion concentration in the solution is equal. When electrolytes are added to the solution, the concentration of ions in the solution increases, and the thickness of the diffusion layer decreases

When the two colloidal particles approach each other, due to the decrease in the thickness of the diffusion layer and the decrease in the potential of the crucible, the force of their mutual repulsion decreases, that is, the intercolloidal repulsion with a high ion concentration in the solution is smaller than the low ion concentration. The suction between the colloids is not affected by the composition of the water phase, but due to the thinning of the diffusion, the distance between them when they collide decreases, so that the suction between them is greater. It can be seen that the combined force of repulsion and attraction has changed from repulsion to suction(the repulsion potential energy has disappeared), and the colloidal particles have rapidly condensed. This mechanism can better explain the deposition phenomenon at the Bay. As freshwater enters seawater, the salt increases, the ion concentration increases, and the stability of the freshwater colloidal particles decreases. Therefore, clay and other colloidal particles are easily deposited at the Bay.

According to this mechanism, when the critical concentration of electrolytes in the solution exceeds the concentration of condensation, there will be no more excess antiions entering the diffusion layer, and it is impossible for the colloidal to change the symbol and stabilize the colloidal particles. Such a mechanism is to explain the effect of electrolytes on the instability of colloidal particles by purely electrostatic phenomena, but it does not consider the role of other properties(such as adsorption) in the process of destabilization, so it can not explain the complex other destabilizing phenomena. For example, when trivalent aluminum salt and iron salt are used as coagulants, the coagulation effect is reduced and even stabilized. Another example is that polymers or polymer organic matter with the same electric number as colloidal particles may have a good condensation effect: the isoelectric state should have the best condensation effect, but often in the production practice the helium potential is greater than zero but the coagulation effect is the least

In fact, the phenomenon of adding coagulant to the aqueous solution to stabilize the colloidal particles involves the interaction between the colloidal particles and the coagulant, the colloidal particles and the aqueous solution, and the coagulant and the aqueous solution. It is a comprehensive phenomenon.

The adsorbed electric neutralization refers to that the particle surface has a strong adsorption effect on the heterosign ion, and the heterosymbol colloidal particle or the chain is separated from the molecule with a heterosign charge. Due to this adsorption, it neutralizes part of its charge and reduces the electrostatic repulsion. Therefore, it is easy to adsorb with other particles and adsorb to each other. At this time, electrostatic gravitation is often the main aspect of these effects, but in many cases, other effects exceed electrostatic gravitation.

For example, using Na + and dodecylammonium ions(C12H25NH3 +) to remove the turbidity caused by a negatively charged silver iodide solution, it was found that the ability of the same monovalent organic amine ion to destabilize is much greater than Na +. The excessive injection of Na + will not cause the colloidal stability, while the organic amine ions are not. When the certain placement is exceeded, the colloidal stability will occur, indicating that the colloidal particles adsorb too many antiions, making the original negative charge change. Into positive charge. When the amount of aluminum salt and iron salt is high, the phenomenon of stabilisation and the charge change sign also occur. The above phenomenon is appropriately explained by the mechanism of neutralization of adsorbed electricity.

Adsorption bridging

Adsorption bridging mechanism mainly refers to the adsorption and bridging of polymer materials and colloidal particles. It can also be understood that two large sized colloidal particles are connected together due to the presence of a hetero-sized colloidal particle in the center. High polymer flocculant with linear structure, they have with parts play a role of colloidal particle surface functional groups, when high polymer contact with colloidal particles, groups with special reaction and colloidal particles surface adsorption, while the rest of the polymer molecules spread in solution, can have vacancy of colloidal particles with another surface adsorption, it ACTS as a bridge to connect the polymer. If less colloidal particles, the polymer stretching part adhesion not second colloidal particles, the stretching part sooner or later will be the original colloidal particles adsorbed on other parts, the polymer can't bridging role, and colloidal particles in a stable state. When the dosage of high polymer flocculant is too large, the surface of colloidal particles will be saturated and stabilize. If the bridged flocculated colloidal particles are subjected to intense and long mixing, the bridged polymer may be detached from the surface of another colloidal particle and rewound back to the surface of the original colloidal particle, causing a re-stable state.

Adsorption on the surface of the polymer in colloidal particles derived from various physical chemistry, such as van der Waals force, electrostatic force, hydrogen bonding, coordination bond and so on, depending on the polymer colloidal particle surface with both the characteristics of chemical structure. This mechanism can explain the phenomenon that non-ionic type or ionic type macromolecular flocculants with the same electric number can obtain good flocculation effect.

Sediment trap mechanism

When metal salts (such as aluminum sulfate and ferric chloride) or metal oxide and hydroxide (such as lime) as a coagulant, when the additive quantity is big enough to rapidly precipitation metal hydroxide (such as Al (OH) 3, Fe (OH) 3, Mg (OH) 2 or metal carbonate (CaCO3), the colloidal particles in the water can be the sediment in the formation of the trap. When the precipitate is positively charged (Al(OH)3 and Fe(OH)3 within the neutral and acidic pH range), the precipitation speed can be accelerated by the presence of anions in the solution, such as silver sulfate ions. Colloidal particles in addition the water itself can be used as the metal oxide deposits formed the core of oxygen, so the best coagulant dosing quantity and the concentration of the substance to be inversely proportional to, the colloidal particles, the more the less metal coagulant dosing quantity.

CAS No : 12042-91-0

CAS No : 101707-17-9