1.Identification

1.1 GHS Product identifier

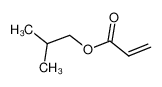

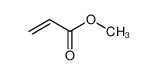

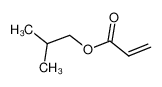

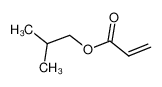

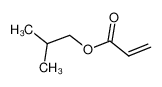

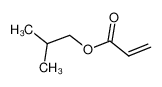

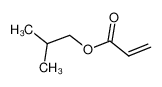

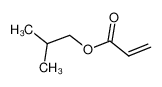

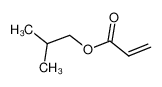

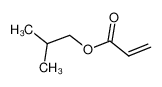

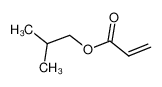

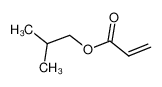

| Product name | Isobutyl acrylate |

|---|

1.2 Other means of identification

| Product number | - |

|---|---|

| Other names | 2-Propenoic acid, 2-methylpropyl ester |

1.3 Recommended use of the chemical and restrictions on use

| Identified uses | For industry use only. Intermediates |

|---|---|

| Uses advised against | no data available |

1.4 Supplier's details

| Company | MOLBASE (Shanghai) Biotechnology Co., Ltd. |

|---|---|

| Address | Floor 4 & 5, Building 12, No. 1001 North Qinzhou Road, Xuhui District, Shanghai, China |

| Telephone | +86(21)64956998 |

| Fax | +86(21)54365166 |

1.5 Emergency phone number

| Emergency phone number | +86-400-6021-666 |

|---|---|

| Service hours | Monday to Friday, 9am-5pm (Standard time zone: UTC/GMT +8 hours). |

2.Hazard identification

2.1 Classification of the substance or mixture

Flammable liquids, Category 3

Acute toxicity - Dermal, Category 4

Skin irritation, Category 2

Skin sensitization, Category 1

Acute toxicity - Inhalation, Category 4

2.2 GHS label elements, including precautionary statements

| Pictogram(s) |   |

|---|---|

| Signal word | Warning |

| Hazard statement(s) | H226 Flammable liquid and vapour H312 Harmful in contact with skin H315 Causes skin irritation H317 May cause an allergic skin reaction H332 Harmful if inhaled |

| Precautionary statement(s) | |

| Prevention | P210 Keep away from heat, hot surfaces, sparks, open flames and other ignition sources. No smoking. P233 Keep container tightly closed. P240 Ground and bond container and receiving equipment. P241 Use explosion-proof [electrical/ventilating/lighting/...] equipment. P242 Use non-sparking tools. P243 Take action to prevent static discharges. P280 Wear protective gloves/protective clothing/eye protection/face protection. P264 Wash ... thoroughly after handling. P261 Avoid breathing dust/fume/gas/mist/vapours/spray. P272 Contaminated work clothing should not be allowed out of the workplace. P271 Use only outdoors or in a well-ventilated area. |

| Response | P303+P361+P353 IF ON SKIN (or hair): Take off immediately all contaminated clothing. Rinse skin with water [or shower]. P370+P378 In case of fire: Use ... to extinguish. P302+P352 IF ON SKIN: Wash with plenty of water/... P312 Call a POISON CENTER/doctor/…if you feel unwell. P321 Specific treatment (see ... on this label). P362+P364 Take off contaminated clothing and wash it before reuse. P332+P313 If skin irritation occurs: Get medical advice/attention. P333+P313 If skin irritation or rash occurs: Get medical advice/attention. P304+P340 IF INHALED: Remove person to fresh air and keep comfortable for breathing. |

| Storage | P403+P235 Store in a well-ventilated place. Keep cool. |

| Disposal | P501 Dispose of contents/container to ... |

2.3 Other hazards which do not result in classification

none

3.Composition/information on ingredients

3.1 Substances

| Chemical name | Common names and synonyms | CAS number | EC number | Concentration |

|---|---|---|---|---|

| Isobutyl acrylate | Isobutyl acrylate | 106-63-8 | none | 100% |

4.First-aid measures

4.1 Description of necessary first-aid measures

General advice

Consult a physician. Show this safety data sheet to the doctor in attendance.

If inhaled

If breathed in, move person into fresh air. If not breathing, give artificial respiration. Consult a physician.

In case of skin contact

Wash off with soap and plenty of water. Consult a physician.

In case of eye contact

Rinse thoroughly with plenty of water for at least 15 minutes and consult a physician.

If swallowed

Never give anything by mouth to an unconscious person. Rinse mouth with water. Consult a physician.

4.2 Most important symptoms/effects, acute and delayed

Moderate toxicity when swallowed. Contact with the eyes causes minor irritation no worse than that caused by hand soap. (USCG, 1999)

4.3 Indication of immediate medical attention and special treatment needed, if necessary

Immediate first aid: Ensure that adequate decontamination has been carried out. If patient is not breathing, start artificial respiration, preferably with a demand-valve resuscitator, bag-valve-mask device, or pocket mask, as trained. Perform CPR as necessary. Immediately flush contaminated eyes with gently flowing water. Do not induce vomiting. If vomiting occurs, lean patient forward or place on left side (head-down position, if possible) to maintain an open airway and prevent aspiration. Keep patient quiet and maintain normal body temperature. Obtain medical attention. /Esters and related compounds/

5.Fire-fighting measures

5.1 Extinguishing media

Suitable extinguishing media

This chemical is a combustible liquid. Poisonous gases are produced in fire. Use dry chemical, carbon dioxide, or foam extinguishers. Water may be ineffective. Vapors are heavier than air and will collect in low areas. Vapors may travel long distances to ignition sources and flashback. Vapors in confined area may explode in fire. Containers may explode in fire. Storage containers and parts of containers may rocket great distances, in many directions. If materials or contaminated runoff enters waterways, notify downstream users of potentially contaminated waters. Notify local health and fire officials and pollution control agencies. From a secure, explosion-proof location, use water spray to cool exposed containers. If cooling streams are ineffective (venting sound increases in volume and pitch, tank discolors, or shows any signs of deforming), withdraw immediately to a secure position. If employees are expected to fight fires, they must be trained and equipped.

5.2 Specific hazards arising from the chemical

Excerpt from ERG Guide 129P [Flammable Liquids (Water-Miscible / Noxious)]: HIGHLY FLAMMABLE: Will be easily ignited by heat, sparks or flames. Vapors may form explosive mixtures with air. Vapors may travel to source of ignition and flash back. Most vapors are heavier than air. They will spread along ground and collect in low or confined areas (sewers, basements, tanks). Vapor explosion hazard indoors, outdoors or in sewers. Those substances designated with a (P) may polymerize explosively when heated or involved in a fire. Runoff to sewer may create fire or explosion hazard. Containers may explode when heated. Many liquids are lighter than water. (ERG, 2016)

5.3 Special protective actions for fire-fighters

Wear self-contained breathing apparatus for firefighting if necessary.

6.Accidental release measures

6.1 Personal precautions, protective equipment and emergency procedures

Use personal protective equipment. Avoid dust formation. Avoid breathing vapours, mist or gas. Ensure adequate ventilation. Evacuate personnel to safe areas. Avoid breathing dust. For personal protection see section 8.

6.2 Environmental precautions

Prevent further leakage or spillage if safe to do so. Do not let product enter drains. Discharge into the environment must be avoided.

6.3 Methods and materials for containment and cleaning up

Evacuate and restrict persons not wearing protective equipment from area of spill or leak until cleanup is complete. Remove all ignition sources. Establish forced ventilation to keep levels below explosive limit. Absorbent may be used to concolidate spills on land (such as sorbent polyurethane foams). Oil skimming equipment may be used for spills on water. Absorb liquids in vermiculite, dry sand, earth, or a similar non-organic materials and deposit in sealed containers. Kepp this chemical out of a confined space, such as a sewer, because of the possibility of an explosion, unless the sewer is designed to prevent the build-up of explosive concentrations. It may be necessary to contain and dispose of this chemical as a hazardous waste. If material or contaminated runoff enters waterways, notify downstream users of potentially contaminated waters. Contact your Department of Environmental Protection or your regional office of the federal EPA for specific recommendations. If employees are required to clean-up spills, they must be properly trained and equipped.

7.Handling and storage

7.1 Precautions for safe handling

Avoid contact with skin and eyes. Avoid formation of dust and aerosols. Avoid exposure - obtain special instructions before use.Provide appropriate exhaust ventilation at places where dust is formed. For precautions see section 2.2.

7.2 Conditions for safe storage, including any incompatibilities

Prior to working with this chemical you should be trained on its proper handling and storage. Before entering a confined space where hexanol may be present, check to make sure that an explosive concentration does not exist. Store in an explosion-proof cool area. Protect for air and light for long-term storage. Where possible, automatically pump liquid from drums or other storage containers to process containers.

8.Exposure controls/personal protection

8.1 Control parameters

Occupational Exposure limit values

no data available

Biological limit values

no data available

8.2 Appropriate engineering controls

Handle in accordance with good industrial hygiene and safety practice. Wash hands before breaks and at the end of workday.

8.3 Individual protection measures, such as personal protective equipment (PPE)

Eye/face protection

Safety glasses with side-shields conforming to EN166. Use equipment for eye protection tested and approved under appropriate government standards such as NIOSH (US) or EN 166(EU).

Skin protection

Wear impervious clothing. The type of protective equipment must be selected according to the concentration and amount of the dangerous substance at the specific workplace. Handle with gloves. Gloves must be inspected prior to use. Use proper glove removal technique(without touching glove's outer surface) to avoid skin contact with this product. Dispose of contaminated gloves after use in accordance with applicable laws and good laboratory practices. Wash and dry hands. The selected protective gloves have to satisfy the specifications of EU Directive 89/686/EEC and the standard EN 374 derived from it.

Respiratory protection

Wear dust mask when handling large quantities.

Thermal hazards

no data available

9.Physical and chemical properties

| Physical state | liquid |

|---|---|

| Colour | Clear liquid |

| Odour | Sharply odorous |

| Melting point/ freezing point | -100°C(lit.) |

| Boiling point or initial boiling point and boiling range | 132°C(lit.) |

| Flammability | no data available |

| Lower and upper explosion limit / flammability limit | Lower 1.9%, upper 8.0% (in air) (% by vol) |

| Flash point | 32°C |

| Auto-ignition temperature | 340°C (USCG, 1999) |

| Decomposition temperature | no data available |

| pH | no data available |

| Kinematic viscosity | 0.822 CP at 70 deg F |

| Solubility | Slightly soluble |

| Partition coefficient n-octanol/water (log value) | log Kow = 2.22 |

| Vapour pressure | 0.062mmHg at 25°C |

| Density and/or relative density | 0.89g/mLat 25°C(lit.) |

| Relative vapour density | 4.42 (Air = 1) |

| Particle characteristics | no data available |

10.Stability and reactivity

10.1 Reactivity

no data available

10.2 Chemical stability

Stable under recommended storage conditions.

10.3 Possibility of hazardous reactions

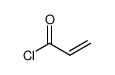

Flammable when exposed to heat or flame ...ISOBUTYL ACRYLATE is an acrylate ester. Esters react with acids to liberate heat along with alcohols and acids. Strong oxidizing acids may cause a vigorous reaction that is sufficiently exothermic to ignite the reaction products. Heat is also generated by the interaction of esters with caustic solutions. Flammable hydrogen is generated by mixing esters with alkali metals and hydrides. Polymerizes readily in the presence of heat and light generating much heat; reacts with strong oxidants. REF [Handling Chemicals Safely, 1980. p. 235].

10.4 Conditions to avoid

no data available

10.5 Incompatible materials

Forms explosive mixture with air. Heat and contamination may cause polymerization. Reacts with strong acids, aliphatic amines, alkanolamines.

10.6 Hazardous decomposition products

When heated to decomposition it emits acrid smoke and toxic fumes.

11.Toxicological information

Acute toxicity

- Oral: LD50 Rat oral 7070 mg/kg

- Inhalation: no data available

- Dermal: no data available

Skin corrosion/irritation

no data available

Serious eye damage/irritation

no data available

Respiratory or skin sensitization

no data available

Germ cell mutagenicity

no data available

Carcinogenicity

no data available

Reproductive toxicity

no data available

STOT-single exposure

no data available

STOT-repeated exposure

no data available

Aspiration hazard

no data available

12.Ecological information

12.1 Toxicity

- Toxicity to fish: LC50 Pimephales promelas (Fathead minnows, 29 days old, mean length 18.5 mm, mean weight 0.1 g) 2.09 mg/L/96 hr (95% confidence limit 1.92-2.28 mg/L); flow through, 24.0°C, hardness 45.3 mg/L (CaCO3), pH 7.61, dissolved oxygen 7.1 mg/L, alkalinity 49.8 mg/L (CaCO3) />97% purity

- Toxicity to daphnia and other aquatic invertebrates: EC50 Daphnia magna 9.7 mg/L/48 hr, endpoint: immobilization

- Toxicity to algae: no data available

- Toxicity to microorganisms: no data available

12.2 Persistence and degradability

AEROBIC: By analogy to butyl acrylate, which biodegrades readily in the MITI test(1), biodegradation of isobutyl acrylate may by an important environmental fate process(SRC). Butyl acrylate, present at 100 mg/L, reached 61% of its theoretical BOD in 2 weeks using an activated sludge inoculum at 30 mg/L in the Japanese MITI test(1)..

12.3 Bioaccumulative potential

An estimated BCF of 10 was calculated in fish for isobutyl acrylate(SRC), using a log Kow of 2.22(1) and a regression-derived equation(2). According to a classification scheme(3), this BCF suggests the potential for bioconcentration in aquatic organisms is low(SRC).

12.4 Mobility in soil

The Koc of isobutyl acrylate is estimated as 66(SRC), using a water solubility of 2,000 mg/L(1) and a regression-derived equation(2). According to a classification scheme(3), this estimated Koc value suggests that isobutyl acrylate is expected to have high mobility in soil.

12.5 Other adverse effects

no data available

13.Disposal considerations

13.1 Disposal methods

Product

The material can be disposed of by removal to a licensed chemical destruction plant or by controlled incineration with flue gas scrubbing. Do not contaminate water, foodstuffs, feed or seed by storage or disposal. Do not discharge to sewer systems.

Contaminated packaging

Containers can be triply rinsed (or equivalent) and offered for recycling or reconditioning. Alternatively, the packaging can be punctured to make it unusable for other purposes and then be disposed of in a sanitary landfill. Controlled incineration with flue gas scrubbing is possible for combustible packaging materials.

14.Transport information

14.1 UN Number

| ADR/RID: UN2527 | IMDG: UN2527 | IATA: UN2527 |

14.2 UN Proper Shipping Name

| ADR/RID: ISOBUTYL ACRYLATE, STABILIZED |

| IMDG: ISOBUTYL ACRYLATE, STABILIZED |

| IATA: ISOBUTYL ACRYLATE, STABILIZED |

14.3 Transport hazard class(es)

| ADR/RID: 3 | IMDG: 3 | IATA: 3 |

14.4 Packing group, if applicable

| ADR/RID: III | IMDG: III | IATA: III |

14.5 Environmental hazards

| ADR/RID: no | IMDG: no | IATA: no |

14.6 Special precautions for user

no data available

14.7 Transport in bulk according to Annex II of MARPOL 73/78 and the IBC Code

no data available

15.Regulatory information

15.1 Safety, health and environmental regulations specific for the product in question

| Chemical name | Common names and synonyms | CAS number | EC number |

|---|---|---|---|

| Isobutyl acrylate | Isobutyl acrylate | 106-63-8 | none |

| European Inventory of Existing Commercial Chemical Substances (EINECS) | Listed. | ||

| EC Inventory | Listed. | ||

| United States Toxic Substances Control Act (TSCA) Inventory | Listed. | ||

| China Catalog of Hazardous chemicals 2015 | Listed. | ||

| New Zealand Inventory of Chemicals (NZIoC) | Listed. | ||

| Philippines Inventory of Chemicals and Chemical Substances (PICCS) | Listed. | ||

| Vietnam National Chemical Inventory | Listed. | ||

| Chinese Chemical Inventory of Existing Chemical Substances (China IECSC) | Listed. | ||

16.Other information

Information on revision

| Creation Date | Aug 10, 2017 |

|---|---|

| Revision Date | Aug 10, 2017 |

Abbreviations and acronyms

- CAS: Chemical Abstracts Service

- ADR: European Agreement concerning the International Carriage of Dangerous Goods by Road

- RID: Regulation concerning the International Carriage of Dangerous Goods by Rail

- IMDG: International Maritime Dangerous Goods

- IATA: International Air Transportation Association

- TWA: Time Weighted Average

- STEL: Short term exposure limit

- LC50: Lethal Concentration 50%

- LD50: Lethal Dose 50%

- EC50: Effective Concentration 50%

References

- IPCS - The International Chemical Safety Cards (ICSC), website: http://www.ilo.org/dyn/icsc/showcard.home

- HSDB - Hazardous Substances Data Bank, website: https://toxnet.nlm.nih.gov/newtoxnet/hsdb.htm

- IARC - International Agency for Research on Cancer, website: http://www.iarc.fr/

- eChemPortal - The Global Portal to Information on Chemical Substances by OECD, website: http://www.echemportal.org/echemportal/index?pageID=0&request_locale=en

- CAMEO Chemicals, website: http://cameochemicals.noaa.gov/search/simple

- ChemIDplus, website: http://chem.sis.nlm.nih.gov/chemidplus/chemidlite.jsp

- ERG - Emergency Response Guidebook by U.S. Department of Transportation, website: http://www.phmsa.dot.gov/hazmat/library/erg

- Germany GESTIS-database on hazard substance, website: http://www.dguv.de/ifa/gestis/gestis-stoffdatenbank/index-2.jsp

- ECHA - European Chemicals Agency, website: https://echa.europa.eu/

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

More Suppliers>>Hangzhou J&H Chemical Co., Ltd.

CHINA

Purity: >97%

Lead Time: 7 Day(s)

Price: -

Henan Coreychem Co.,Ltd

CHINA

Purity: 99.99%

Lead Time: 3 Day(s)

Price: -

Hangzhou DayangChem Co., Ltd

CHINA

Purity: 98%

Lead Time: 7 Day(s)

Price: -

Skyrun Industrial Co., Limited

CHINA

Purity: 99%

Lead Time: 7 Day(s)

Price: -

CHINA

Purity: 99%

Lead Time: 3 Day(s)

Price: Min $100 /kg

Shanghai Yusi Chemical Co., Ltd.

CHINA

Purity: 99%,%

Lead Time: 10 Day(s)

Price: Min $41.33 /ml

Shanghai Yusi Chemical Co., Ltd.

CHINA

Purity: 99%,%

Lead Time: 10 Day(s)

Price: Min $578.67 /l

Shanghai Yusi Chemical Co., Ltd.

CHINA

Purity: 99%,%

Lead Time: 10 Day(s)

Price: Min $18.17 /ml

Beijing Coupling Technology Co., Ltd.

CHINA

Purity: 97%

Lead Time: 7 Day(s)

Price: Min $58.33 /ml

TCI-Tixi Ai (Shanghai) Chemical Industry Development Co., Ltd.

CHINA

Purity: 99%

Lead Time: 7 Day(s)

Price: Min $40 /ml